Turn Grip Standard Screws

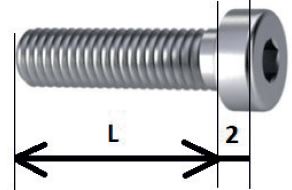

For parts that are screw mounted, we offer a standard range of screws that will match the panel thickness, you have,

use the thickness of the plate where the Turn-Grip is mounted to determine your screw part number

material: stainless steel A2

| Part Nr. | Length L | Plate thickness P |

| TGSM305S | 5 | - |

| TGSM306S | 6 | 0.8-1.0 |

| TGSM308S | 8 | 1.1-3.0 |

| TGSM310S | 10 | 3.1-5.0 |

| TGSM312S | 12 | 5.1-7.0 |

| TGSM314S | 14 | 7.1-9.0 |

| TGSM316S | 16 | 9.1-11.0 |

| TGSM318S | 18 | 11.1-13.0 |

| TGSM320S | 20 | 13.1-15.0 |

| TGSM322S | 22 | 15.1-18.5 |

| TGSM325S | 25 | 18.6-22.2 |

| TGSM330S | 30 | 22.3-27.2 |

| TGSM335S | 35 | 27.3-32.5 |

| TGSM340S | 40 | 32.6-37.4 |

When using standard screws, drill 6mm diameter holes in your frame. Standard screws help as they are a back-up for shear strength protection. When using countersunk screws, you do not need to drill holes in your frame! Make sure you do not install them more than 0.25 mm flush into your panel! (for screw with length 25mm, and high precision, max. 0.05mm below surface flush) Remark: All cross pins are treated with a Lubricant Molybdenum Disulphide Dry Moly Lube, application temperature rated from -150°C +400°C, which makes them look black on the lubricated side. We recommend to apply Molykote G Rapid+ after each 1000 cycles with the high precision series. Indication of open & closed position is recommended to be printed on your panel: other indication options are available upon request.